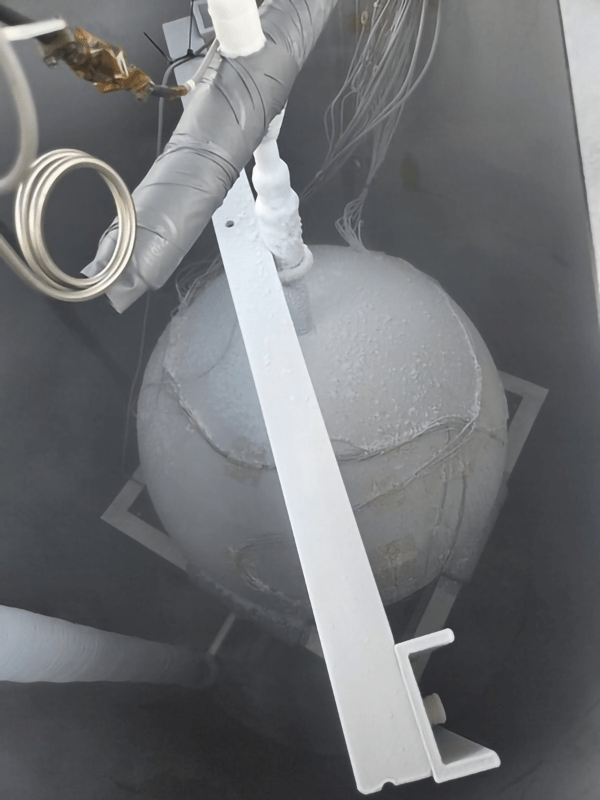

A large titanium fuel tank produced via 3D printing has passed a critical durability test, withstanding extreme temperatures and pressure in a world-first for such a component, according to a recent announcement from the Korea Institute of Industrial Technology (KITECH).

The 640mm diameter vessel, made from Ti64 titanium alloy, withstood pressures of 330 bar while cooled to -196°C with liquid nitrogen. The component was developed through a joint project with the Korea Aerospace Research Institute (KARI), KP Aviation Industries, AM Solutions, and Hanyang University.

This development addresses the limitations of conventional manufacturing by enabling faster and more customized production of space components. It also offers a strategic advantage by helping secure a domestic supply chain and strengthening the competitiveness of the private-led ‘New Space’ industry.

Overcoming the limits of traditional forging

High-pressure vessels are essential components in space launch vehicles, used for supplying liquid fuel and controlling the vehicle’s attitude. They must be both lightweight and durable, maintaining stable performance when in contact with cryogenic propellants.

Until now, these parts have been primarily manufactured using the forging method, where titanium alloy is pressed into a fixed mold. This process is effective for standardization, but it struggles to accommodate the demand for custom parts in various shapes and sizes.

“In the past era of state-led space development, using standardized parts was not an issue. However, we are now in the ‘New Space’ era, where private companies develop small launch vehicles for their own specific purposes,” explained Dr. Lee Hyub, a principal researcher at KITECH. “The need for custom parts has grown, with companies now requesting 110L tanks instead of the standard 130L, or alternative shapes such as cylinders.”

This reliance on forging presents challenges, as large-scale titanium forging facilities are not common. South Korea has typically imported these components primarily from Ukraine. Recent geopolitical events have raised concerns about supply chain stability, highlighting the need for domestic production capabilities. The forging process also involves long lead times, often six months to a year, which can slow down vehicle development schedules.

To address these issues, the research team employed the Directed Energy Deposition (DED) 3D printing process. This technique uses a laser to melt a metal wire, building a component layer by layer from a digital design. The process involved fabricating two separate hemispheres, which were then machined and welded to form the vessel. The printing process took three days, and the entire manufacturing cycle was completed within a few weeks, representing a significant reduction in lead time.

One of the project’s hurdles was overcoming industry skepticism toward using 3D printing for such a critical application. There was a perception that the potential for micro-defects made the technology unsuitable for high-risk components like pressure vessels, where failure could have severe consequences. “While 3D printing had been used to create shapes before, no component had ever been certified for safety under the extreme conditions of an actual launch,” said Dr. Lee. “It was a high-stakes test where failure meant the prototype could explode like a bomb, so initially, we faced significant reluctance from others to even make the attempt.”

The prototype was ultimately submitted for the cryogenic pressure test at KARI. Inside a safety facility enclosed by concrete barriers, the vessel was cooled to -196°C and successfully withstood 330 bar of pressure, a force 165 times greater than standard tire pressure. The result demonstrated that the 3D-printed component could meet the high reliability standards required for demanding space environments.

“I was relieved that the test concluded without any accidents,” Dr. Lee remarked. “I feel a great sense of pride in proving that the 3D printing process can be used even for high-performance components.”

The joint research team plans to conduct further tests, including repeated pressurization at operational levels, to prepare the technology for practical application.

The story was produced in partnership with our colleagues at Popular Science Korea.