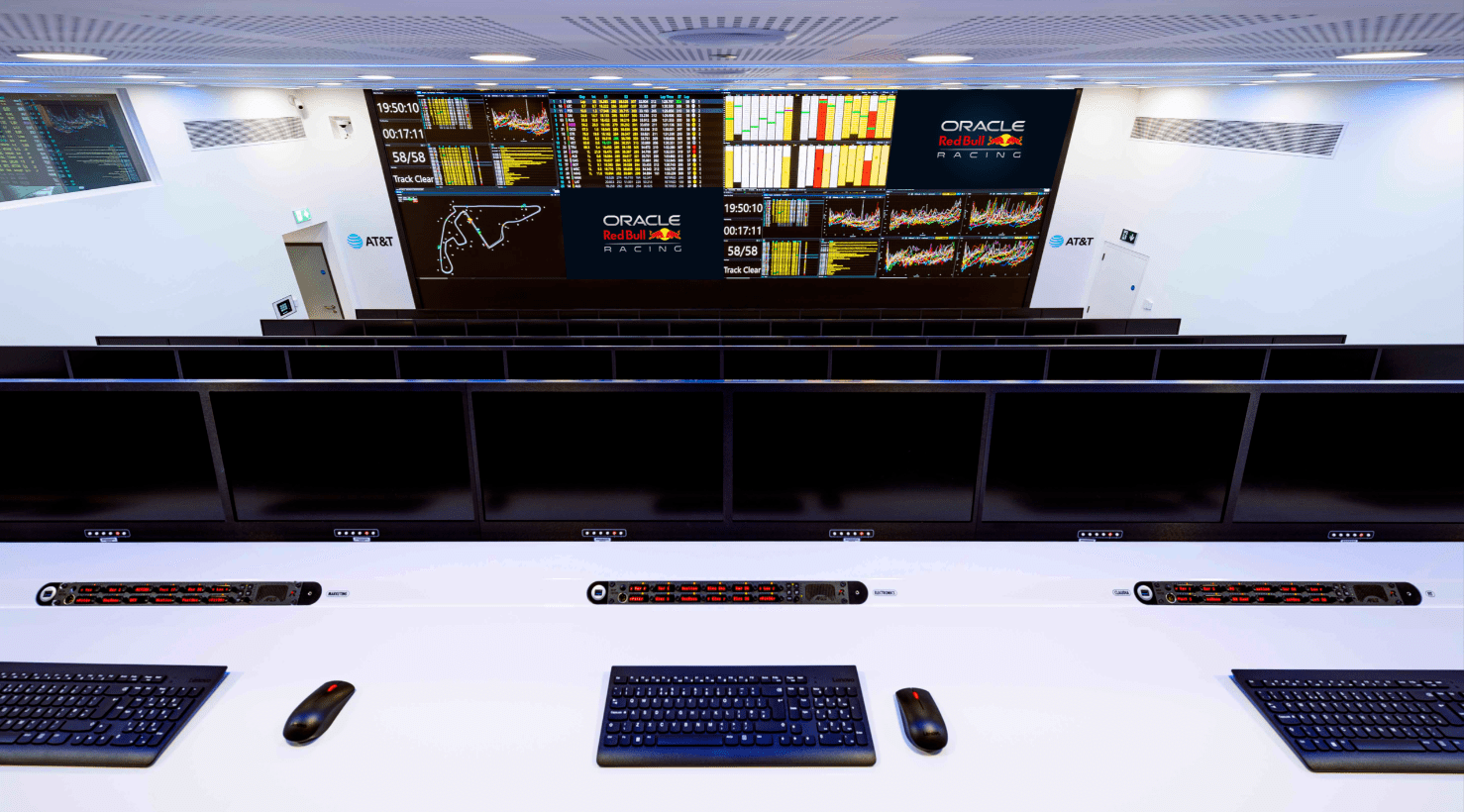

Formula One is unquestionably fast. The motorsport’s multi-million-dollar cars achieve speeds over 210 miles per hour on tracks that bend and twist wildly. Even the pit crews operate at warp speed; a complete tire change at all four corners must be accomplished in two seconds. For the Oracle Red Bull team, the data transmitted from champion driver Max Verstappen’s car to their operations center is even faster. Exponentially so.

Every millisecond counts, and the data supports tiny increments of improvement with every realization. Nearly 800 sensors are integrated into the car, and data flows to the Oracle Red Bull team via AT&T-laid fiber optic cables back to the racing team’s operations center in Milton Keynes, UK. That lightning-quick information transfer is invisible to the fans, but it’s unquestionably critical to operations.

“During the race there is a lot of analysis going on; it’s constant,” Verstappen told Popular Science. “Of course, the more information the pit has and at the home front in Milton Keynes, the more they can help me throughout the race.”

We’re talking about huge numbers flying across the network to the tune of about 4 billion equations during a race weekend. Statistics is king, and the Oracle Red Bull team is betting on unfailing connectivity to predict what will work best. That includes this weekend’s Las Vegas F1 race.

Betting on the Monte Carlo simulation process

Morgan Maia, senior technical partnerships manager at Oracle Red Bull Racing, says 120 to 130 people are dedicated to data processing and analysis every weekend. It’s important to convey real-time data between the track and the factory to make sure the team has the right information at the right time and at the right place, he says.

The team uses what’s called a Monte Carlo simulation, which uses these billions of equations to generate models that predict success while making tiny incremental changes to influence the best outcome. Data is fed rapid-fire into the system and it calculates scenarios, supplying information on tire degradation rates, fuel consumption, and more. The team has multiple chassis, rear aero wings, and other interchangeable parts on hand so they can exercise their options as conditions change.

Even before hitting the track, the technical team will run two billion equations. The other half of the four billion equations is used to help with racetime strategy. All of this happens in the background, as Verstappen suits up for practice and then at the starting line.

“The faster you can analyze all the data you can get, the faster you can find solutions or improvements to the car,” Verstappen says. “There are a lot of people at the factory to help out behind the scenes.”

AT&T has been working side by side with Oracle Red Bull since 2011. As one metric of its growth, the number of sensors on the car has increased from 250 to 800 over the years. Incidentally, the sensors on the Oracle Red Bull F1 machine aren’t stuck on like Post-It notes. Each is integrated into the design of the car and built in from the start. Engineers ensure each tiny data sensor is part of the chassis, the tires, the electronics, and other elements. Information about the brakes, the cooling system, and the aerodynamics are fed into the simulations to see where adjustments are needed. Verstappen also receives information about his driving and what competitors are doing, as needed.

“If it is going really well, they don’t say much because that means I’m doing a good job,” Verstappen says. “Of course, some races are more difficult in general and the more data you can get, the better. It varies a lot, from breaking points to driving lines to decisions we need to make about the tires.”

Looking to 2026 and using the data efficiently

F1 imposed a $140 million cost cap for 2025, which is intended to even the playing field for racing teams across the board. That $140 million includes car parts, some personnel salaries, travel, and development. As a result, the cost of the data must be kept in check, and partnering with Oracle and AT&T saves the team money: Instead of having to buy a complete server farm, the data runs through the cloud.

Big changes are coming to F1 in 2026, including a new chassis design and a redesigned hybrid power unit. Sustainable fuels will be mandated, and movable front and rear wings with active aerodynamics will be required for closer (read: more exciting, more hair-raising) racing. The Oracle Red Bull team is ready to tackle what’s coming with everything they’ve learned through their parentship with AT&T and beyond.

Verstappen says he puts a lot of trust in his data and engineering team. While he understands the data reads, he knows there is a massive number of people working to optimize the car’s–and his–performance.

“I look at the data, but at the same time we have a lot of smart engineers at Red Bull that are going over every part of the car to optimize every single bit,” he says. “Basically, it’s never good enough and you want to find more performance. You’re constantly working on it.”

For all of his appreciation for massive amounts of data, the four-time F1 champion says a human driver is still the X factor that makes racing interesting. He admits there’s a little self-promotion in that statement, but he’s not wrong. Even highly-trained drivers can be unpredictable and inconsistent, which is all part of the thrill.

“The driver is still such an important factor,” Verstappen says. “At the end of the day, I think the driver is still the most important sensor in the car.”