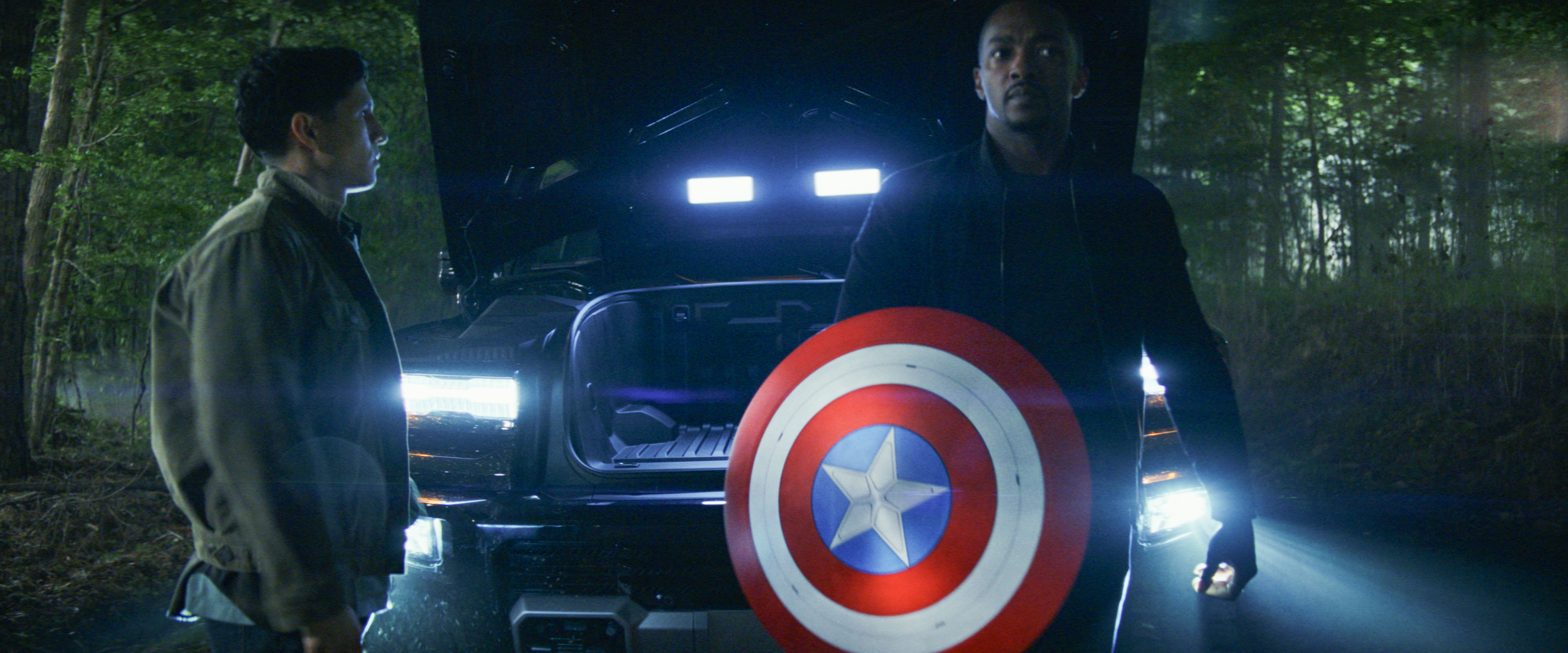

Captain America’s star-spangled shield can stand up against the universe’s most powerful forces all thanks to vibranium. This fictional and nearly indestructible element absorbs and releases huge amounts of kinetic energy. It is also the stuff of dreams for real materials scientists.

“It’s an interesting piece because it covers pretty much all the mechanical properties that you’re looking for,” Ricardo Castro, a materials scientist currently teaching at Lehigh University in Pennsylvania, tells Popular Science. “Since the shield is so good at everything, it’s very fascinating and inspiring for materials scientists.”

Castro teaches a course called Engineering Superheroes, which combines engineering lectures with physical demonstrations that reveal how materials could help give superheroes their powers. While their creations aren’t exactly as strong as the hammer of the mighty Thor, students will take what they’ve learned to create their own hammers, battery packs, and even shields.

So, what materials would go into a real world shield like the one Captain America uses? Like figuring out time travel to retrieve all six Infinity Stones, it’s a little complicated.

Facing Thanos

A material’s atomic structure–how the individual atoms are arranged–gives it various properties like flexibility vs. stiffness. The strength of the metal is related to how the atoms slide against one another and the microstructure of the material itself.

“You can’t really say that one metal is necessarily stronger than another, because it typically depends on what you’re using this for,” explains Castro. “Let’s say that Thanos has my shield and is compressing it. My need for a material to withstand the compression is different from my need for a material to take a bullet.”

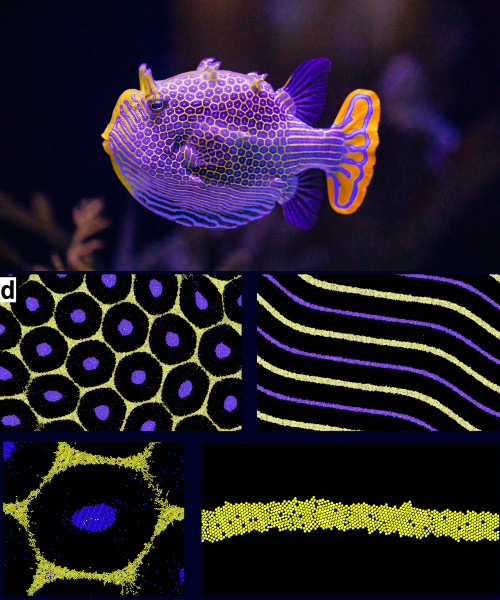

A material made from tungsten carbine could square off against compressive forces. The atoms in this compound are packed so tightly that they can’t be separated and are very resistant to pressure. It actually works with a material commonly found in kitchens–a ceramic mug. When a porous material like a ceramic mixes with metal, it can create a new–and sometimes better–mixed material.

“If you have a ceramic material coated with metal layers, you can actually get a little bit of duality. We call these metal matrix composites, where you have metals and ceramic particles or structures distributed across,” says Castro.

Deflecting Hydra’s bullets

However, the strength of a giant, powerful alien is not the only force an Avenger must vanquish. During Captain America: The First Avenger, Captain America’s shield is seen blocking bullets from guns in World War II. For this to work, the shield needs to withstand their fast and localized strikes. To best deflect against bullets, we have to look at how the metal is organized.

“Every metal is organized into crystals and the atoms that form these crystals get together in very predictable ways,” explains Castro. “With metals, we have multiple crystals together called grains.”

[ Related: Actor Anthony Mackie and marine biologist Jasmin Graham talk sharks. ]

The orientation of these crystals can affect a material’s strength. To withstand that speedy centralized force of a bullet, a shield could use a copper-tantalum alloy. Developed by the United States Army, this alloy is nanocrystalline and uses tiny crystals and the power of the nanoscale similar, to the kevlar in bulletproof vests. It mixes copper–a soft and malleable material–with the rare Earth element tantalum, which has a high melting point and is very hard.

“You can think about it as a honeycomb. The honey is the copper and the wax and the tantalum is the actual frame that can resist the bullet,” says Castro. “So what resists the bullet is that frame that can basically hold the impact of that ball and stops it.”

Blocking fire

The Avengers are constantly up against explosions and flames, whether from the infighting in Captain America: Civil War or from alien armies in Avengers: Endgame. To block fire, you need a material that can best stop heat from flowing through it. This allows Steve Rodgers or Sam Wilson to hold onto it for as long as possible without burning themselves.

Most metals are thermal conductors and can heat up much quicker than other surfaces. Ceramic materials with their purpose air pockets can help balance this out. Ceramics have very strong covalent bonds that cannot move as freely and become more insulated.

“This is used in space technologies. NASA uses ceramics as protective coatings that can withstand the heat of a reentry so that a spacecraft doesn’t explode,” says Castro. “So if we have ceramic material and these layers of porous materials coated with metal layers, then you can actually get a little bit of the duality. Composite materials mix the best world of two materials into one.”

[Related: How the burning heart of a jet engine functions without melting. ]

Standing up to Thor’s hammer

To Castro, one of the most exciting aspects of Captain America’s shield is the way that it can bounce back and withstand blunt force. In the real world, if you throw an object at a wall, it will not come back to you at the exact same speed.

“It contradicts all the laws of physics,” laughs Castro.

However, there are some materials that act a bit like this called shape memory alloys. Nitonol is a nickel titanium alloy, which mixes nickel and titanium to create a material with some degree of super plasticity.

“Super plasticity means that the material would actually bounce back at as high a level, going back to its shape, and returning without deforming whatsoever,” explains Castro.

This plasticity is what helps the shield withstand the crushing force of Thor’s hammer.

A ‘beautiful universe’

In the real world, developing better and more sustainable materials that can scale up is arguably the biggest–but most exciting–challenge. According to Castro, space, aviation, and electric car batteries are only a few of the realms that will benefit from continued research into the next generation of materials.

While we (hopefully) won’t be fighting an extraterrestrial army any time soon, developing real new materials will help send Artemis astronauts into space safely, protect soldiers in the line of duty, and maybe even defend New York City from a Chitauri attack, if needed.

“It’s a beautiful universe of materials,” says Castro.