Decades ago, my parents bought their first non-GM car: a 1990 Honda Accord. It had a manual transmission, and my mom eventually passed it down to my sister, who kept it for many years before it was retired. I remember my dad telling me that he liked that it was built in America, supporting American workers in Ohio.

Today, that Marysville, Ohio plant (along with its nearby counterparts in Anna and East Liberty) is in the process of a major transformation to the tune of about $1 billion. By retooling these manufacturing facilities, Honda is poised to build internal combustion, hybrid-electric, and battery-electric vehicles on the same production lines. Ultimately, this adds a level of flexibility to the automaker’s process and the option to adjust each segment up or down as needed.

Honda’s new “thin, light, and wise” strategy is in full effect in Ohio. The first vehicle built on the new line will be Acura’s new battery-electric RSX SUV later this year, followed by production models of the 0 Saloon and Honda 0 SUV prototypes unveiled at CES in January. Among other firsts, the company has integrated a new lightweight, high-strength welding process that will benefit every car made here.

Chopping the weld current for stronger fusing

Honda launched its iconic Gold Wing touring motorcycle 50 years ago in Japan. The company moved production to its Marysville plant a few years later, and the facility has been steadily growing ever since the first Accord sedans began rolling off the line in late 1982.

Fast forward to 2025, and Honda is focused on its goal: for 100 percent of its vehicle sales to be the zero-emissions type by 2040. At the same time, Honda (like its rival Toyota) is hedging its bets on ICE and hybrids to meet demand and increase efficiency.

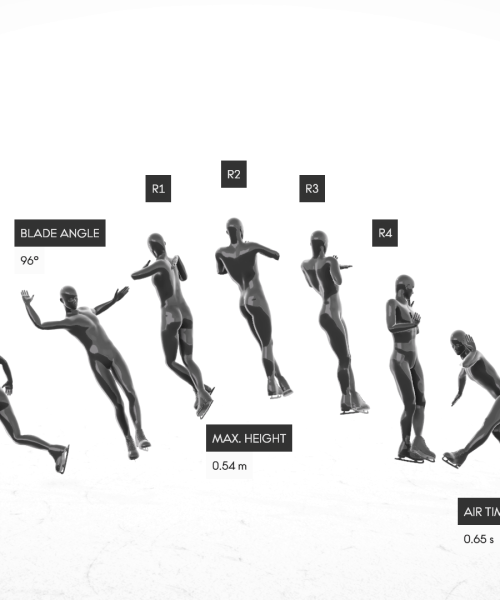

By using a special welding technique Honda calls CDC for “constant DC chopping”, the automaker says its combining two technologies. One maintains a specific waveform with a high peak current and technology that keeps the heat constant by automatically controlling the pause time. In other words, Honda combined the best attributes of conventional DC and AC welding methods for a better result.

Forty-year Honda veteran Tim Leopold is leading the transformation of the Marysville Auto Plant, where more than 4,000 employees show up for work. He says that this kind of welding is new to not just this plant, but for Honda globally. The company hasn’t used this method anywhere else in high volume manufacturing.

Any kind of spot welding operation requires current and heat in order to create a nugget to fuse the weld together, he explains.

“There is no bead; you’re just essentially pinching metal together with what’s called a weld gun, but it’s essentially like a clamp,” Leopold continues. “You’re squeezing the metal to eliminate any air gaps and then you’re applying a current from one side of the weld tip to the other side of the weld tip.”

By “chopping” the current using the CDC method, technicians can control the nugget temperature differently than they might have with DC welding. While there’s nothing wrong with the older process, Leopold says, it’s very difficult to use it when fusing together various-thickness metals. It’s even harder to do with a range of thickness metals in a unique order, which is what Honda is doing at the EV hub.

The “old-fashioned style welding” burns through the thinner metal faster because it heats up more quickly but doesn’t allow for full nugget penetration into the thicker metal, Leopold explains, so the weld quality is not as strong. For instance, if two one-millimeter pieces of metal are sandwiched around a three-millimeter piece, that requires a different weld than a consistent-thickness stack. It requires control over the weld nugget temperature so the technicians don’t burn through the thinner one before they get the heat penetration needed for the thicker one, Leopold says.

Giant megacasting machines move in

Another major development for Honda in Ohio is the addition of six 6,000-ton megacasting machines. These units cast, machine, and join battery cases at the Anna engine plant, then the cases are sent to the Marysville auto assembly plant. About an hour or so away, a new battery plant was recently opened to complete the circle. Honda and LG Energy Solution partnered to invest $3.5 billion in the battery facility, and the investment is estimated to total $4.4 billion overall.

According to the North American Die Casting Association, the parts cast on these massive high-pressure machines will be the largest parts Honda has ever produced. Future Honda EVs are expected to incorporate megacasting (sometimes called gigacasting) for other parts as well, like engine and body components.

The manufacturer could have built a new plant to house these giant units of equipment, says executive chief engineer of Honda Development & Manufacturing of America Mike Fischer. However, it conserves capital and opens the door for the multiple-powertrain approach. Along with CDC welding technology, line consolidation and space optimization, Honda is calling it a “second founding” for its Ohio production plants. I can’t wait to see what the upcoming Honda 0 Saloon looks like in production form. It won’t be long before we find out.

More deals, reviews, and buying guides