The phrase “the world’s smallest violin” is dripping with sarcasm and reserved for disdain, but for some researchers it’s a mark of pride. Thanks to the latest nanotechnology tools, a team at the United Kingdom’s Loughborough University recently crafted what is literally the world’s smallest violin. At only 35 micrometers long and 13 micrometers wide, the “instrument” is thinner than a human hair and makes tardigrades look imposing by comparison.

Don’t expect to hear any scaled down sonatas, however. In this case, engineers designed a nanoscale image of a violin instead of a playable instrument. Regardless, the milestone wasn’t intended as a stunt—it’s helping experts push the boundaries for future generations of electronics and computer chips.

For decades, electronics designers and manufacturers have consistently miniaturized projects while simultaneously boosting performance benchmarks. Computer chips have consistently doubled their capacity roughly every 1.5 to 2 years, in keeping with a trajectory known as Moore’s Law. First proposed by Intel co-founder Gordon Moore in 1965, his namesake theory has largely held up even after 65 years. But at a certain point in the not-too-distant future, manufacturers will simply run out of physical, upgradable space for data–which is where quantum computing may come into play.

Until then, researchers must turn to increasingly advanced techniques to design nanoscopic electronics. One such approach is nanolithography—and Loughborough University’s Physics department recently acquired a new system designed for just such tasks.

“Our nanolithography system allows us to design experiments that probe materials in different ways—using light, magnetism, or electricity—and observe their responses,” experimental physics professor Kelly Morrison said in a recent university profile. “Once we understand how materials behave, we can start applying that knowledge to develop new technologies, whether it’s improving computing efficiency or finding new ways to harvest energy.”

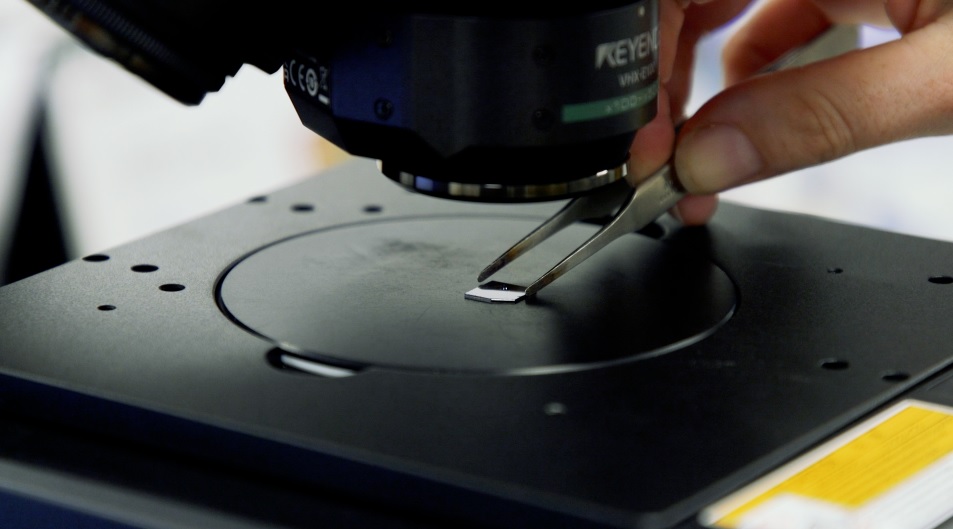

Before that, Morrison and colleagues need to understand the ground level science. In order to do this, they worked with a NanoFrazor. The garage-sized tool designed by Heidelberg Instruments relies on a particular technique known as thermal scanning probe lithography to assemble nanoscale structures. Essentially, the bulky NanoFrazor array culminates in a microscopically small, needlelike tip capable of observing and interacting with atomic-sized targets. Once heated to a specified temperature ranging between 75 to 2012 degrees Fahrenheit, the tip then burns away material or etch patterns as needed.

After sketching their violin schematic using a rendering program, the team coated a glass chip with two layers of gel-like polymer to create the basis of what’s known as a resist. The chip was next placed into the NanoFrazor, at which point its heated tip seared the violin design into the surface polymer layer. From there, the team developed the resist by dissolving the now-exposed underlayer, leaving behind an instrument-shaped empty space. A layer of platinum was then applied over the chip before rinsing it in acetone to remove any residual material.

While it took months to test, refine, and improve their techniques, the final process only took the NanoFrazor about three hours to complete its project. While admiring the violin’s details requires a microscope, some eagle-eyed individuals may be able to spot it on their own. That said, it will still look like a speck of dust.

With their test project completed, researchers have already moved on to more advanced investigations. One current project involves developing alternatives to magnetic data storage methods, while another is examining how heat may help design faster, more efficient storage and processing capabilities.

“Though creating the world’s smallest violin may seem like fun and games, a lot of what we’ve learned in the process has actually laid the groundwork for the research we’re now undertaking,” said Morrison. “But first, we [needed] to understand the fundamental science and this system enables us to do just that.”